Роторная дробилка

Доступны самые разные модели | Получите бесплатный прайс-лист!

- Размер частиц корма: ≤1000 мм

- Производительность: 15-850 т / ч

- 【Применимый материал:】Известняк, гранит, мрамор, базальт, железная руда, речная галька, сланцы, голубой камень, уголь, галька, строительные отходы.

- 【Применимые поля:】Широко используется в различных отраслях дробления руды, железных дорог, автомобильных дорог, энергетики, цемента, химической, строительной и других отраслях промышленности.

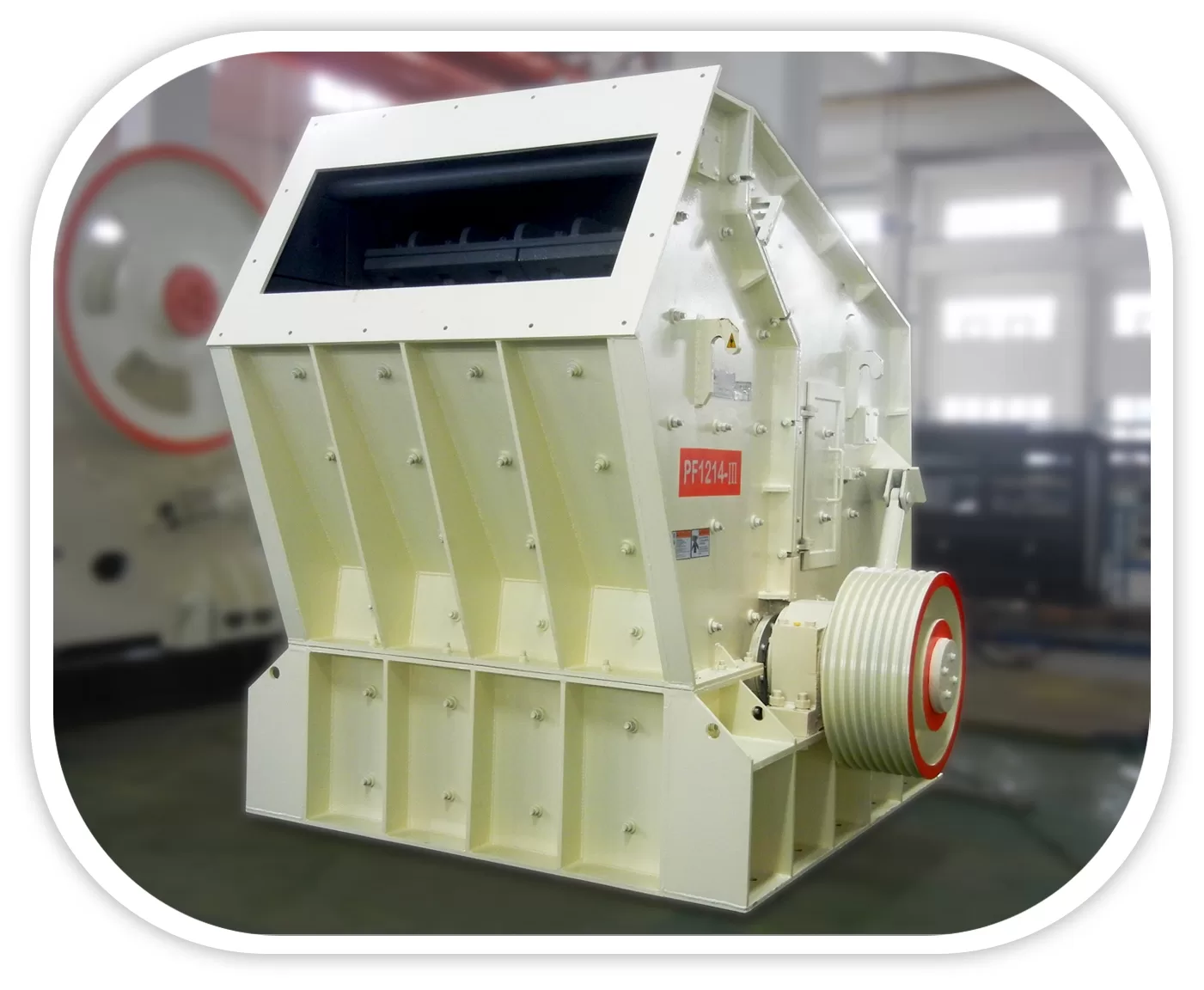

Что такое ударная дробилка?

Impact crusher is a kind of crusher which utilizes impact energy to crush materials. It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with feed size not more than 500mm and compressive strength not more than 350MPa, and is widely used in all kinds of ore crushing, railroad, highway, energy, cement, chemical, construction and other industries. It adopts updated manufacturing technology and unique structural design. The finished product is cubic with no tension or cracks. Our impact breaker series is divided into two series: two-chamber and three-chamber series.

Применение ударной дробилки

Impact crushers are versatile machines that have a wide range of applications across various industries. Here are some of the main applications of impact crushers:

- Добыча полезных ископаемых: Impact crushers are commonly used in mining and quarrying operations to crush rocks, ores, and other hard materials. They are particularly effective in reducing large rocks to smaller, more manageable sizes.

- Совокупное производство: In the construction industry, impact crushers are used to produce aggregates such as sand, gravel, and crushed stone. These materials are used in concrete, asphalt, and other construction applications.

- Утилизация: Impact crushers are also extensively used in recycling applications, where they can process concrete, asphalt, bricks, tiles, and other waste materials. This helps to reduce the amount of material sent to landfills and allows for the reuse of these materials in new construction projects.

- Обращение с отходами: Impact crushers can be used to reduce the volume of waste materials, making them easier to transport and dispose of. They can handle a variety of waste types, including plastics, wood, paper, and more.

- Снос: In demolition projects, impact crushers can be used to process concrete, bricks, and other materials from demolished structures. This allows for the recycling of these materials and reduces the amount of waste generated by demolition projects.

- Другие инновации: Impact crushers can also be used in a variety of other applications, including glass recycling, ceramics production, and the processing of non-metallic minerals.

The versatility and high efficiency of impact crushers make them a valuable asset in many industries that require material reduction and recycling.

Принцип работы ударной дробилки

Here is a brief overview of the working principle of an impact crusher:

- Для кормления: The material to be crushed is fed into the impact crusher through a feeding inlet or hopper. This feeding process can be automated or manual, depending on the crusher model and the specific application.

- Ударное дробление: Inside the crusher, there is a rotor or hammer assembly that rotates at high speed. This rotor or hammer assembly has impact hammers or blow bars that are mounted on it. As the rotor rotates, the hammers hit the material that is falling or passing through the crusher, applying impact forces on the material. The high-speed rotation and impact forces cause the material to break into smaller pieces.

- Rebounding and Secondary Crushing: The broken pieces of material rebound from the crusher walls or anvils (if present) and collide with each other or with the hammers again, undergoing further crushing. This process of rebounding and secondary crushing continues until the material is reduced to the desired size.

- Screening and Discharge: The crushed material is then passed through a screening mechanism, which separates the material into different size fractions based on the size of the openings in the screen. The material that meets the desired size specifications is discharged from the crusher through a discharge outlet, while the oversize material is recirculated for further crushing.

- Система контроля: Modern impact crushers are equipped with advanced control systems that monitor and regulate various parameters such as rotor speed, feed rate, and discharge size. These control systems ensure efficient and reliable operation of the crusher.

Принцип работы ударной дробилки

Структурные преимущества ударной дробилки ZDM

- Сверхмощное строительство: Constructed with robust materials and components for durability in harsh crushing environments.

- Optimized Crushing Chamber: Chamber design maximizes crushing efficiency while minimizing wear.

- Adjustable Gap: Allows for adjustment of crushing gap based on material properties and output requirements.

- Простота обслуживания: Design facilitates easy cleaning and replacement of wear parts, minimizing downtime.

- Integrated Screening System: May feature an integrated screening system for classifying crushed material to meet different size specifications.

- Усовершенствованная система управления: Advanced control system may be available to monitor and adjust key parameters for efficient and stable operation.

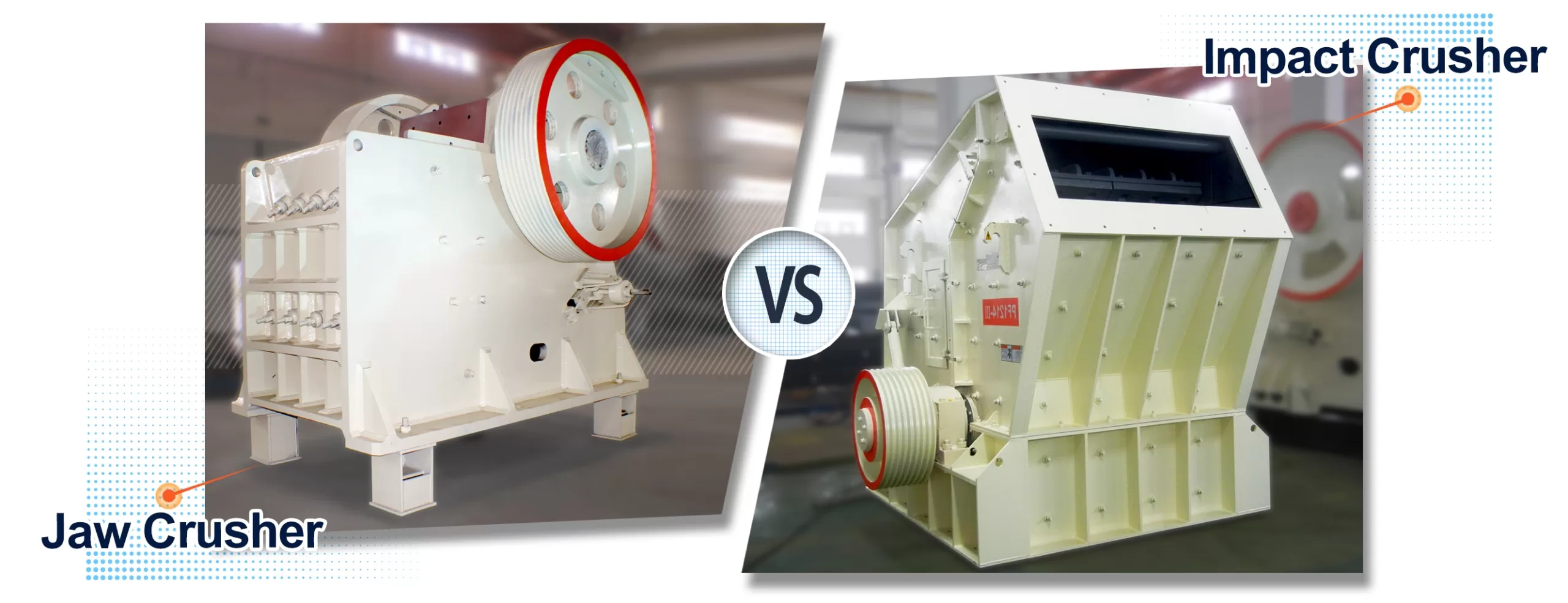

Ударная дробилка VS Щековая дробилка

| Спецификация | щековая дробилка | Роторная дробилка |

|---|---|---|

| Размер входного отверстия | Несколько моделей разных размеров | Больший размер |

| Принцип работы | компрессия | закупорка |

| Применение | Первичный процесс дробления | Процесс вторичного дробления |

| Приспособляемость | Адаптируется для шахт и заводов разных размеров. | Менее адаптируемый |

| Использование в камнедробильных установках | Обычно используется | Может использоваться в сочетании с вибрационным ситом и вибрационным питателем. |

| Использование на заводе по производству песка | Может использоваться в сочетании с машиной для производства песка, моечной машиной для песка, ситом и питателем. | Не часто используется |

Ударная дробилка VS Щековая дробилка

Основные характеристики

| Модель | Спецификация (Мм) | подача открытие (Мм) | Максимум Размер кормления (Мм) | Пропускная способность (т/ч) | Мощность (КВт) | В общем Размеры (Д×Ш×В) (Мм) | Всего Вес (т) |

| PF-1007 | Φ1000 × 700 | 400 × 730 | 300 | 30-70 | 4П 37-45 | 2330 × 1660 × 2300 | 12 |

| PF-1010 | Φ1000 × 1050 | 400 × 1080 | 350 | 50-90 | 4П 45-55 | 2370 × 1700 × 2390 | 15 |

| PF-1210 | Φ1250 × 1050 | 400 × 1080 | 350 | 70-130 | 6П 110 | 2680 × 2160 × 2800 | 17.7 |

| PF-1214 | Φ1250 × 1400 | 400 × 1430 | 350 | 80-180 | 6П 132 | 2650 × 2460 × 2800 | 22.4 |

| PF-1315 | Φ1320 × 1500 | 860 × 1520 | 500 | 100-280 | 6П 200 | 3180 × 2720 × 3120 | 27 |

| PF-1320 | Φ1300 × 2000 | 993 × 2000 | 500 | 140-380 | 6П 250 | 3220 × 3100 × 3120 | 34 |

| PF-1520 | Φ1500 × 2000 | 830 × 2040 | 700 | 200-550 | 4П 315-400 | 3959 × 3564 × 3330 | 50.6 |

| PF-1820 | Φ1800 × 2000 | 1260 × 2040 | 800 | 400-800 | 4П 630-710 | 4400 × 3866 × 4009 | 83.21 |

ПОДОБНЫЕ ТОВАРЫ

щековая дробилка

Щековая дробилкаГрубое дроблениеУзнайте цену и поддержкуЩёковая дробилка в основном используется для среднего дробления различных руд и сыпучих материалов. Он может измельчать материалы с прочностью на сжатие не более 320 МПа. Существует два метода дробления…

Машина для производства песка

Машина для производства пескаМелкое дроблениеУзнайте цену и поддержкуМашина для производства песка подходит для мягких, среднетвердых и очень твердых рудных материалов с твердостью не выше 320 Па. Кроме того, мы обычно называем ее машиной для производства песка VSI. Он имеет характер…

конусная дробилка

Получите цену и поддержку Whatsapp +8618637198006 Электронная почта: zd-machine@kssb.cn Получите цену Оставьте сообщение Принцип работы: ,

Пружинная конусная дробилка

Получить цену и получить поддержку Whatsapp +8618637198006 Электронная почта: zd-machine@kssb.cn Получить цену Оставить сообщение Линия обогащения руды: Пружинная конусная дробилка подходит для дробления железной руды, медной руды и других металлических руд в обогатительной…

Гидравлическая конусная дробилка

Получите цену и поддержку Whatsapp +8618637198006 Электронная почта: zd-machine@kssb.cn Получите цену Оставьте сообщение,

Конусная дробилка Symons

Получите цену и поддержите WhatsApp +8618637198006 Электронная почта: zd-machine@kssb.cn Получить цену Оставить сообщение ,

Молотковая дробилка

Получите цену и поддержку Whatsapp +8618637198006 Электронная почта: zd-machine@kssb.cn Получите цену Оставьте сообщение,

Рулонные дробилки

Получите цену и поддержку Whatsapp +8618637198006 Электронная почта: zd-machine@kssb.cn Получите цену Оставьте сообщение,

Зубчатая валковая дробилка

Получите цену и поддержку Whatsapp +8618637198006 Электронная почта: zd-machine@kssb.cn Получите цену Оставьте сообщение,

Составная дробилка

Получите цену и поддержите WhatsApp +8618637198006 Электронная почта: zd-machine@kssb.cn Получить цену Оставить сообщение ,

загрузка ...

已经是到最后一篇内容了!

Зонирующая машина

Зонирующая машина